Club Racing and Long Distance Racing Sails

Perfect For:

Club Racers

Long Distance Racers

Perfect For:

Club Racers

Long Distance Racers

If you are a club racer, long distance racer, or just want to outperform the boat coming up on your port side, Racing Laminate sails are a great choice for you.

The basic construction of Racing Laminate sails is the same: the fibers are laid between two pieces of Mylar film. Although the fibers that are used and the process of lamination can change, they are all very similar.

Although there is crosscut racing cloth available, Precision Sails offers a wide range of Tri-Radial rolled Laminate sailcloth. Tri-Radial designs allow sail designers to design a more accurate curve to your sail. This curve allows the sail to develop more lift, pulling the boat forward more than a crosscut sail design.

Polyester: Polyester is used in Dacron sails as well as Laminate sails. In a Laminate sail, the fibers are secured between the Mylar films without being woven together. Polyester is strong, durable, and simple to maintain. If you’re new to purchasing Laminate sails, a Polyester-based sail will offer a lower price point and can take a beating. They do however offer more stretch, both under initial load and over time. This stretching will affect overall performance and lifespan.

Aramids: Aromatic polyamides were first introduced in the early 1960’s. Aramids have excellent resistance to heat and are used extensively in the production of protective apparel, air filtration, thermal and electrical insulation as well as sail making. There have been several brand names used throughout the years that are classified under the generic term Aramids.

Ultra PE (Kevlar, Dyneema, Spectra): These fibers offer very good UV resistance and low stretch. The fiber is costly to manufacture and therefore not often used in smaller boats that don’t produce the loads that would require these types of fibers.

Carbon Fiber: First used in the America’s Cup in 1992, these fibers are the lightest, stiffest fibers on the market. They provide the greatest resistance to stretch under initial load and over the lifetime of the sail. These sails require attention to care so as to avoid broken fibers. Carbon is a brittle material that needs to be rolled for storage and should not be folded or flaked repeatedly.

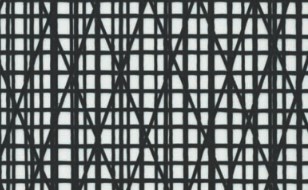

Contender Sailcloth’s Black Polyester ZZP has been developed as an economical alternative for the small boat racing sailor and for one-design classes that have restrictions on higher modulus fiber usage.

Read More

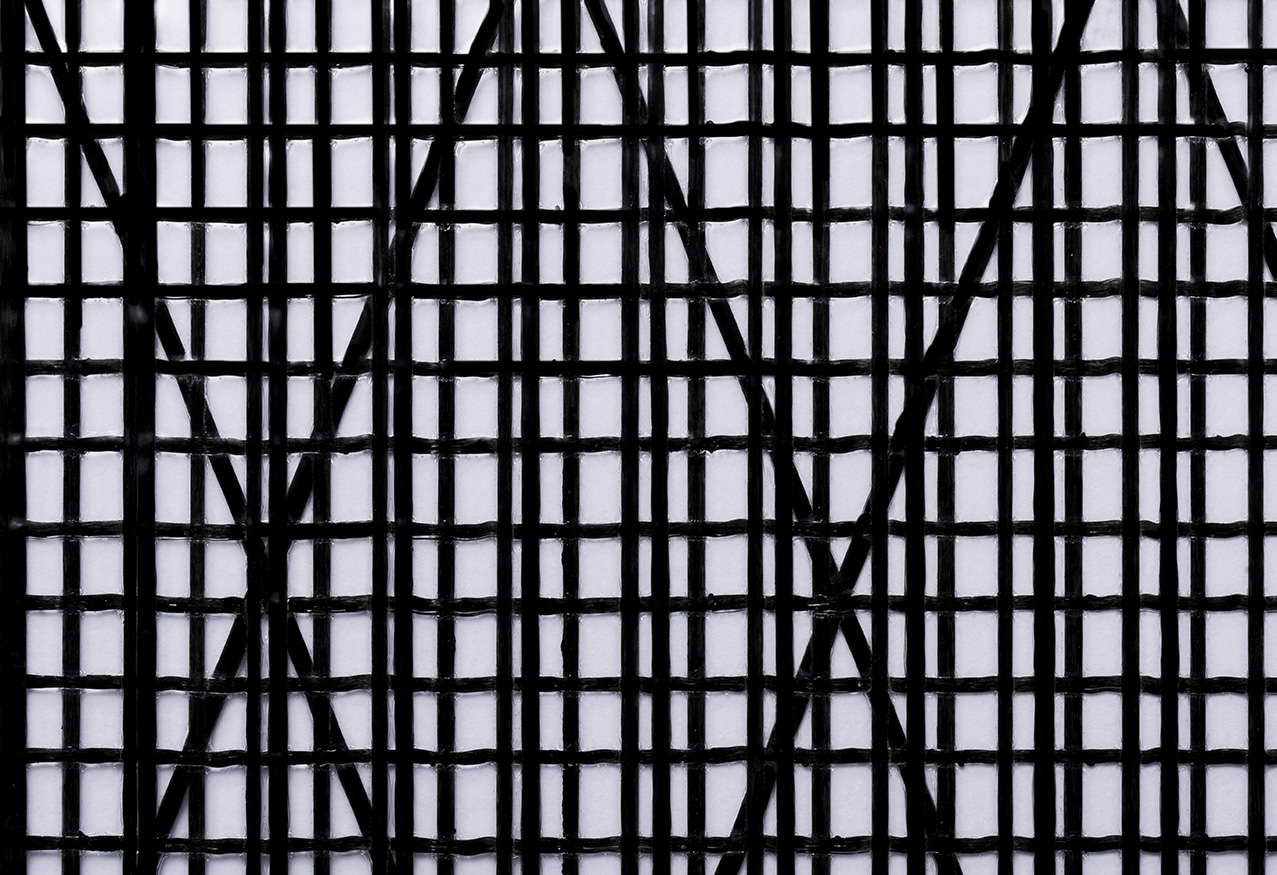

A top choice in racing laminates is the ZigZag Black Aramid Laminate from Contender. It is popular from club through international levels. It is constructed with ZigZag yarn to produce a sail with radial panels that have superior strength.

Read More

Zig Zag Carbon is from Contenders new range of reinforced Carbon-Aramid laminates. They use Carbon and Black Twaron fibers with a Technora cross-ply for a highly durable performance oriented laminate sail.

Read More

Whether you are a competitive sailor or a pleasure cruiser, you are probably looking for a sail that will maintain its shape in the face of a variety of situations. Dimension Polyant has Discontinued Flex Polyester as of 11.14.24

Read More

This radial constructed technora fiber laminate is highly advanced and balanced to prevent unwanted elongation. This cloth utilized two high end technora scrims instead of typical polyester scrim.

Read More

ince 1966 Dimension has been developing fabrics for sailors around the world. Based on their PX Polyester warp-oriented materials, they now offer PXB Polyester.

Read More

Looking for the most durable carbon laminates today’s market has to offer? Look no further and allow us to introduce you to Dimension‑Polyant’s line of GraphX®.

Read More

These fabrics offer stretch resistance and shape retention better than woven sailcloth. They are durable and long lasting.

Read More

For better performance in racing, the DIAX-PP-P fabric will provide a longer life for the sail. It is a new Film-on-Taffeta design that has proven more durable and stronger than DIAX-P and equivalents.

Read More

This material uses the best quality fiber to give you a 0-90 load bearing scrim. With a unique manufacturing technique warp crimp is virtually eliminated and stretch is greatly reduced.

Read More

Because scrim fibers are laid as flat tapes, as opposed to round yarns, thickness is reduced, and adhesion improved. Scrims are created using a process that removes the crimp that gives stretch.

Read MoreOur Sail Consultants are always happy to schedule a time to discuss your boat, sailing location, and experience level to help narrow down the results and provide the best-priced no-obligation quote possible!

Book A Consultation