Anyone looking at replacing their sails will have come across the terms crosscut, and tri-radial. These are the two most common configurations of panel construction in sails.

Watch Sailing Soulianis Explain The Differences

Crosscut vs Tri-Radial

Crosscut

Crosscut sails are made of a series of panels sewn parallel to the foot in a “stacking” pattern. This sail configuration is the most economical of the two as less design time, cutting, and stitching are required during production. Crosscut sails use cloth which have straight fill and crimped warp yarns. This allows the strength of the sail to be maximized by orienting the fill with the load bearing orientation. The cloth used in crosscut sails has a fill stronger than its warp. Due to this sailcloth used in crosscut designs tends to be heavier as more fibers have been added to reduce the stretch of the Dacron. This is one of the common reasons why racing sails are constructed in a tri-radial pattern with laminate sailcloth. Crosscut sails may last for many seasons and it is not uncommon for cruisers to sail for many years without replacing their sails. However, they will begin to lose their sail shape and become blown-out and baggy over time reducing their performance.

Tri-Radial Sails

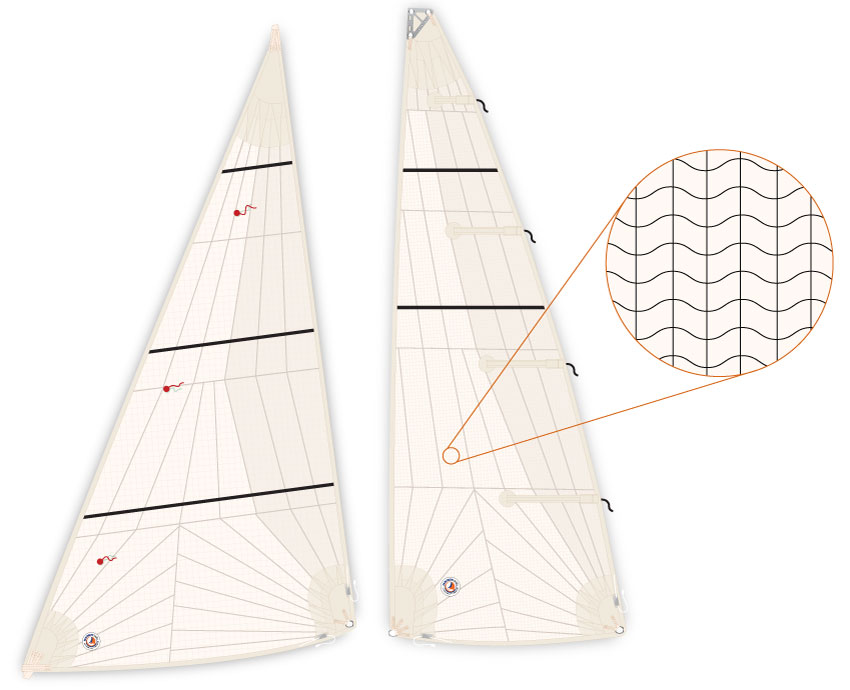

Tri-radial sails are constructed with panels radiating from the three corners of the sail. The panels orient out from the Head, Clew, and Tack and have an almost triangular shape. Typically, tri-radial sails are constructed from laminate and membrane sailcloth due to the increased challenge of creating a warp-oriented material. However, with innovation from companies woven Dacron has become a viable option for tri-radial constructed sails. Challenge Sailcloth’s Warp-Drive sailcloth was the first innovative cloth to have a warp-oriented weave. Tri-radial sails are better for performance as they allow more control over the designed shape of the sail. This increased strength and design ability allows tri-radial sails to maintain their sail shape over their lifespan without the stretching of a crosscut sail. With the new techniques and cloth’s being developed by sail engineers for constructing laminate cloths the usable lifespan of a laminate has never been better. The benefit of this is the ability to retain sail shape from laminate sails from their first to last day of use when they begin to de-laminate.

Woven and laminate Sailcloth

Woven

Woven is the most economical, UV resistant, and popular option when it comes to sailcloth. This is because it is constructed on a loom and long bolts of cloth can be produced efficiently. Most sailcloth is produced with shuttles that move back and forth between alternating layers of fibers. This allows a loom to produce a long bolt of cloth with a crimped warp and a straight fill easily. Woven Dacron’s such as Challenge Sailcloth’s Warp Drive, Dimension Polyant’s Pro Radial, and Contender Sailcloth’s Fibercon Pro Radial are all examples of innovative cloths which weave their warp fibers uncrimped and their fill fibers crimped. This allows for radial constructed sails to be built with specialized woven sailcloth or alternatively, laminates.

Laminate

Laminate sails are made via the process of layering materials on top of each other and laminating them together. A Laminate sail is made of layers formed together. One of these layers is the scrim, which are specific fibers laid in the load bearing directions of the sail to reinforce the sails durability. Taffeta can be found on one or both sides of a laminate sail and acts as a protective layer from UV damage. Certain offshore sailcloth will have a thicker taffeta applied to both sides to prevent damage and prolong its life.

Precision Sails Tri-radial Racing Laminate Sails on SV Nirvana

The Importance of Fibers

Imagine you were playing tug of war with a thick rope. The thick rope will not grow or shrink no matter how hard both sides are pulled on. Now play the same game, with the same forces but with a slinky. A slinky has a defined shape which springs back after being stretched. However, once you apply the same amount of force that is put on the rope that slinky will become permanently deformed and lose all the properties that allow it to do what it was designed for. The rope is like straight fibers, strong and durable when pulled on. And the slinky is like crimped fibers, great at filling space but stretch when used the wrong way. When wind fills your sail and the cloth has pressure applied to it the fibers will either resist stretching or stretch. This is what makes your cloth decision and panel configuration important.

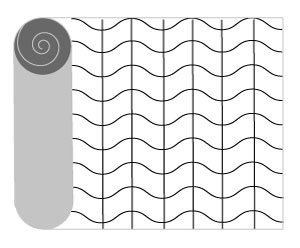

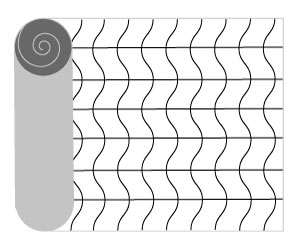

Most cloth is made as a fill oriented cloth, which means the strongest fibers are running along the width of the panels, limiting the maximum panel width to that of the bolt of cloth. Whereas warp oriented cloth has the strongest fibers making up the warp giving a comparatively limitless length of usability.

Fill Oriented Sailcloth

Fill Oriented Sailcloth

Warp Oriented Sailcloth

Warp, Fill, Crimp, Scrim, and Bias

Warp

The long fibers typically oriented in the load bearing direction of the sail and vertical along a bolt of cloth. Fibers which are not crimped are stronger as they have no extra material in their length to stretch. When forces act upon a sail these fibers can disperse the strain exerted greater than crimped fibers.

Fill

The fibers which are typically crimped over the warp fibers to fill the material allowing it to fill with wind. They make up the horizontal direction in a bolt of sailcloth.

Crimp

The interweaving of fibers under and over alternating fibers in cloth. When stress is applied to the cloth in the direction of the crimped fibers it can stretch and change the shape of the cloth. Panel configuration is key to controlling which fibers the load is distributed over.

Scrim

A series of fibers laid on a sail which are bonded together in a lattice to increase the stretch resistance of the cloth. This is one of the processes involved in creating a laminate sail and one of the reasons they retain their sail shape their entire life. Scrim fibers are placed both up-down as well as left-right in order to increase the load-bearing properties of the sail in both directions.

Bias

The diagonal direction of force applied to the cloth. Woven sailcloth does not have fibers aligned with this direction causing the forces to be divided between the warp and fill fibers. However, companies have developed cloths which “interlock“ allowing the load to be dispersed more efficiently.

Cosmetics

Cosmetics are another aspect of these two configurations to consider. Laminate sails in a tri-radial construction have a unique and eye-catching appearance to them as the scrim fibers (usually black) allow light to shine through them. Woven sailcloth in a tri-radial sail have beautiful leading lines which seem to point in on itself. Cross-cut sails have a flatter appearance, as the parallel panels hide the stitching better than a radial sail.

SV Delos Crosscut Mainsail and TriRadial Mizzen

Choosing a Sail

Deciding on which configuration is the best for you depends on many factors. If you are determined that performance and lasting sail shape are your priority, then a tri-radial sail is your best option. If you are alright with sacrificing sail shape for longevity and reduced cost, then a crosscut sail is the way to go.

To recap, tri-radial sails will retain their sail shape for their entire life until they delaminate. Whereas, crosscut sails will last much longer and cost less but sacrifice shape retention and performance. Your boat, location, conditions, and experience are all important determiners of your sail selection. Each sailor should decide for themselves what configuration and cloth is their best choice.

In a market where there are many different cloth options and little information to be found it can be hard to decide. Precision Sails is here to help. If you are still not sure about what to choose you can check out our cloth info page to learn more about sailcloth or request a quote to speak to a sail consultant about your options.

Sailing Soulianis

Sailing Soulianis recently did a video discussing their choice to go with a tri-radial dacron sail and do an excellent job at comparing the differences and features of each! Check out their video below:

From Our Ask Precision Sails Series

What Is The Most Important Part Of A Sail’s Design?

Should I Upgrade To A Laminate?

How To Inspect Dacron Sails From A Newly Purchased Boat

Post Updated: April 29 2020